Electric Power Engineering

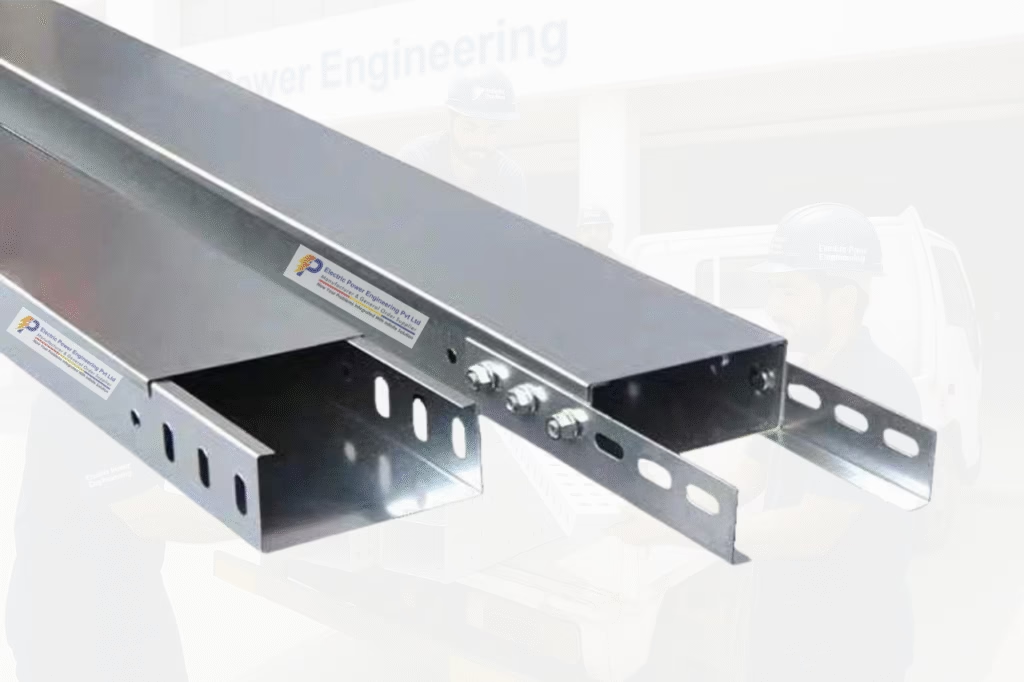

Cable Tray manufacturer & Supplier in pakistan

Cable Tray Types, Sizes, and Complete Guide (Pakistan 2026)

Cable trays are essential components of modern electrical installations, used to support, manage, and protect cables in industrial, commercial, and residential sectors. This complete guide explains cable tray types, sizes, materials, applications, installation practices, and selection criteria—fully optimized for Pakistan’s electrical standards.

What Is a Cable Tray?

A cable tray is a structural system used to safely support and route electrical cables, communication wires, and power distribution lines. Cable trays provide mechanical protection, organized routing, and easy maintenance.

Why Cable Trays Are Important in Electrical Installations?

Prevent cable damage

Improve heat dissipation

Ensure safe cable routing

Reduce installation time

Allow future expansion

Provide organized cable management

Cable Tray Types (Complete Classification)

Below are the most commonly used electrical cable tray types in Pakistan.

Perforated Cable Tray

A perforated cable tray is manufactured from mild steel or galvanized steel and features evenly spaced holes across the bottom and side rails. These holes improve ventilation, reduce cable heat buildup, and allow easy drainage in moisture-prone areas.

Industrial electrical wiring Power distribution inside factories Commercial buildings Suspended ceiling systems

Prevents overheating of wires Easy cable tie-down points Cost-effective & durable Can be paired with covers for dust protection

A solid bottom cable tray has a complete metal sheet base with no ventilation holes. This protects cables from dust, moisture, and external physical contact.

Prevents dust contamination Shields cables from physical damage Ideal for clean environments

Ladder Cable Tray (Heavy-Duty & Long Span Support)

A ladder cable tray is built using two side rails connected by horizontal rungs. This structure provides strong mechanical support and maximum air circulation.

Highest load-bearing capacity among all cable trays Ideal for long cable routes Best ventilation prevents insulation damage Reduces cable stress on bends

High-voltage power cables Outdoor cable routing Industrial plants & refineries Generator and transformer connections

Production of standard and customized trays, cable supports, and accessories.

No heat accumulation Superior structural strength Perfect for thick armoured cables Low maintenance

Wire Mesh Cable Tray (Basket Tray for IT & Low-Voltage Cables)

Made from welded steel wires shaped into a basket, wire mesh trays offer exceptional flexibility and lightweight installation.

Sleek & modern design Easy to cut, bend, and shape onsite Excellent airflow for sensitive equipment

Channel Cable Tray (C-Type or U-Type Tray)

Channel cable trays are made in a “U” or “C” shape, ideal for low-volume cable runs and short distances.

Strength & Properties

Slim profile

Cost-effective

Ideal for areas with limited space

Best for

Residential buildings

Small offices

Control cables & signal wires

Get a Quote

sales@epepk.com

Need more help?

Need help? Our team is here to assist you with cable tray selection, pricing, customization, and technical support.

0300-9444-973

0300-9444-907

Every product we manufacture from cable trays and conduit pipes to earthing systems and solar structures goes through strict testing, inspection, and quality control to ensure unmatched durability and reliability in every installation.

Support

Newsletter

Sign up our newsletter to get update information, news and free insight.